P-39D

The Bell XP-39 Airacobra prototype was rolled out at Wright Field on 6 April 1939. The aircraft was essentially designed around the new Oldsmobile 37-mm cannon. Bell's chief designer, Robert Wood, opted to locate the engine in the center of the aircraft so that the nose would be free for a powerful array of armament. In his design Woods used the new Allison V-1710 engine with the new B-5 turbocharger. Maximum power output would be achieved at 20,000 feet. On April 6 the aircraft reached a speed of 390 mph. During subsequent tests it reached 398 mph. It also had an excellent rate of climb reaching 20,000 feet in five minutes. At the time no airplane in Europe could match this performance, however the aircraft had no armor, and no self sealing fuel tanks as the USAAC had not specified them.

After factory tests were completed the XP-39 was turned over to the engineers at Wright Field. Wright Field considered that reducing the frontal drag of the aircraft would improve its performance, however in the case of the P-39 they went too far. The NACA engineers felt the turbocharger air intakes were causing too much drag and had to be removed. The cockpit was lowered and two feet clipped from the wings. a less powerful Allison engine with a mechanical supercharger was installed. This deprived the aircraft of its excellent high altitude performance though low level maneuverability was enhanced. Larry Bell and Robert Wood were not happy with the improvement but with Bell Aircraft on the brink of bankruptcy neither Bell nor Wood wanted to lose an order for the new aircraft so they accepted all the changes. Since America needed modern aircraft quickly, with war looking imminent, this was convenient for everybody.

The USAAC was satisfied with the low altitude performance and that high altitude use was not going to la a requirement and therefore directed that the twelve YP-39s be completed without turbochargers. The first YP-39 was flown on 13 September, 1940 with the V-1710-37 engine providing 1,090 hp and driving a Curtiss Electric propeller. The first few were not armed but later machines were equipped with the 37-mm cannon with 15 rounds and two 30 caliber machine guns with 500 rounds per gun. armor protection was provided for the pilot. So equipped the performance dropped to a maximum speed of 368 mph at 15,000 feet and an altitude of 20,000 feet could be obtained in 7.3 minutes. The thirteen YP-39s were delivered between 6 September and 16 December 1940. They were used only for evaluation and tests.

The USAAC was generally pleased with the Airacobra and an initial order of 80 production aircraft was issued on 10 August 1939. The first P-39C, as the first production models were classified, flew in January 1941. The P-39C was identical to the YP-39, with the exception of the engine which was a 1,150 hp Allison V-1710-35. The Army discovered immediately that the P-39C was not ready for combat since it had no armor of self sealing tanks. Because of that only 20 P-39Cs were built. On September 14, 1940 the initial order for 80 P-39Cs was amended to provide for self sealing fuel tanks. the remaining 60 planes on the order were completed to this standard and were re designated as P-39Ds. Armament was one 37-mm cannon, two 50 caliber machine guns and two 30 caliber machine guns, all in the nose.

On 13 September 1940 394 P-39Ds were ordered. It was the first Airacobra which could be considered as being combat ready. The P-39D differed from the P-39C mostly in having better armament. It had four wing mounted 30 caliber machine guns in the wings with 1000 rounds per gun and two 50 caliber machine guns in the nose with 200 rounds per gun and the 37-mm cannon with an increased capacity of 30 rounds. Bullet proof windshield panels were added and some armor protection for the pilot. Self sealing fuel tanks were introduced which reduced the internal fuel capacity from 115 Imperial gallons to 100 Imperial gallons. A 72.4 Imperial gallon drop tank could be carried on a rack fitted underneath the fuselage. Also a 300 lb or 600 lb bomb could be carried.

While

the

evolution of the P-39 continued throughout the war I will stop here

as the P-39D is the subject of this kit. The P-39 was born into a

rapidly changing air warfare environment and it never quite caught up

with the changes required. Coupled with some unusual stability effects

caused by the engine being located over the center of gravity, the

type

gained a reputation as a dangerous machine. Bell fighters were never

to

gain popularity in the west. In conclusion the P-39 was a relative

failure because of errors by both the engineers and establishment of

the USAAC. Had they not ordered removal of the turbo supercharger from

the XP-39, the US could have entered the war with a potent fighter.

The

later P-63 showed just how good the concept could be but by the time

it

appeared it had been tainted by the P-39's reputation and saw almost

no

USAAF service, much to the benefit of the Soviet Air Force which took

almost all of the production.

The Kit

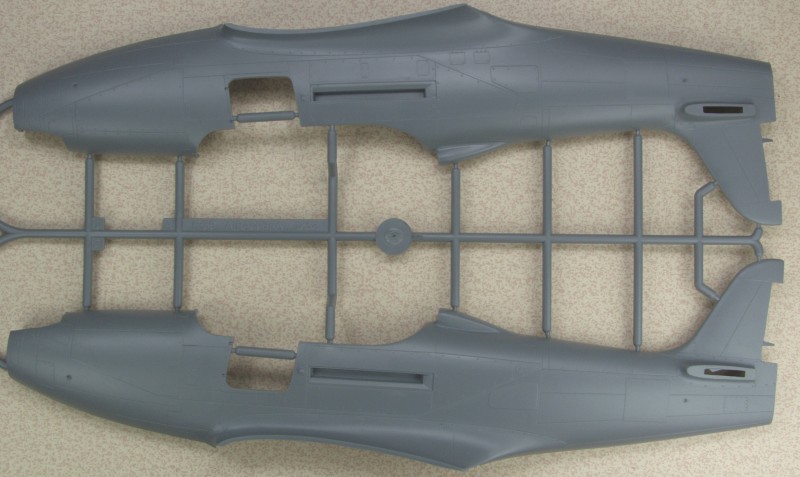

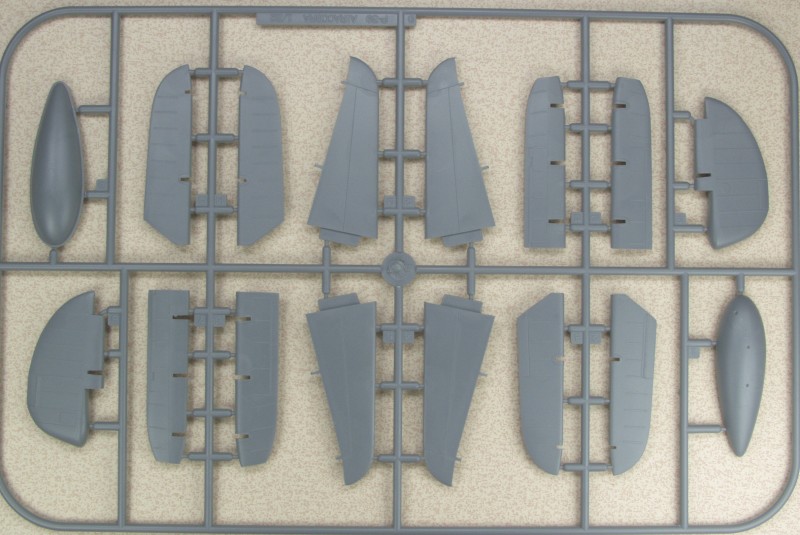

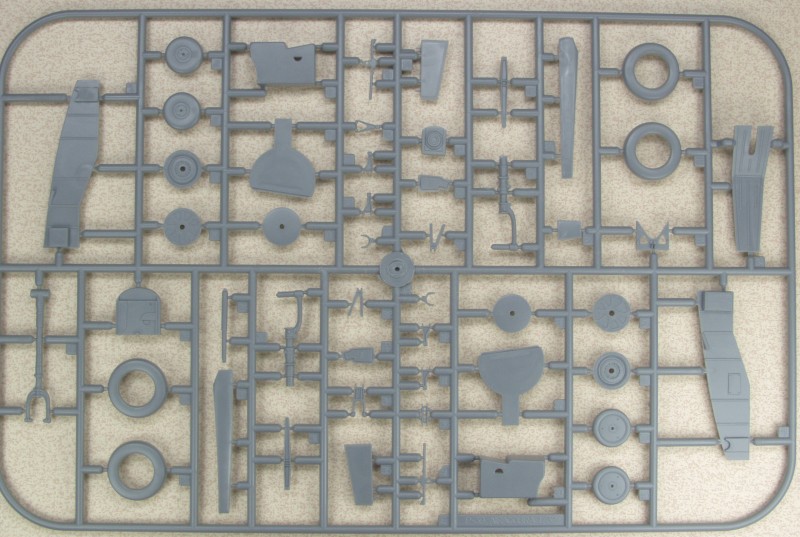

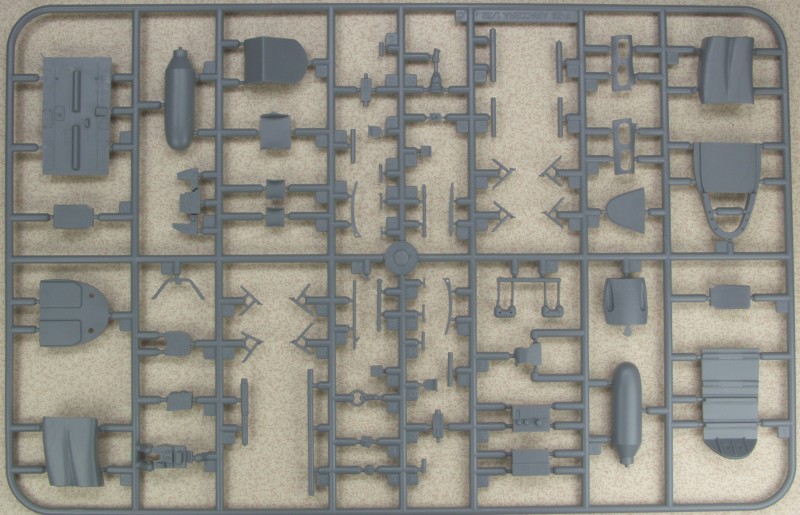

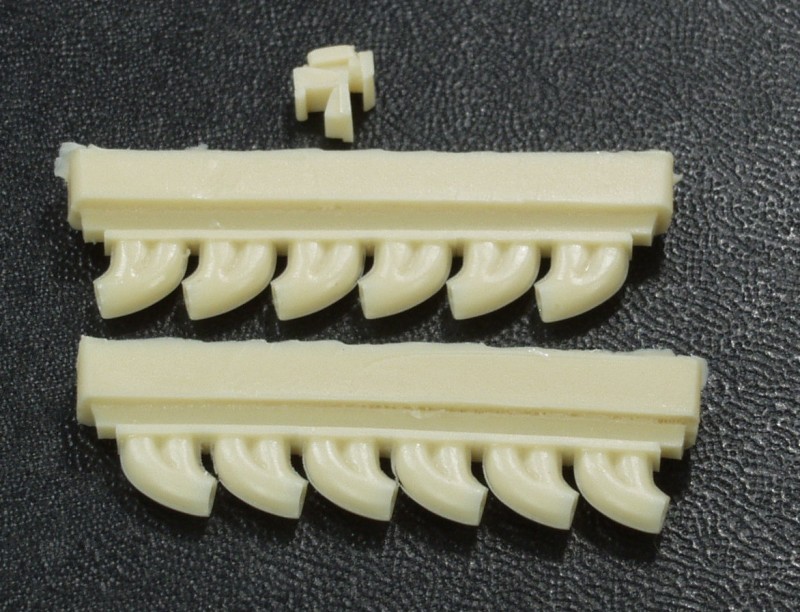

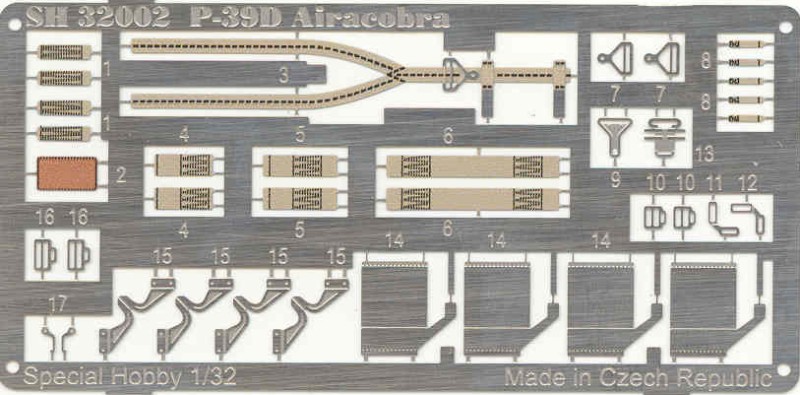

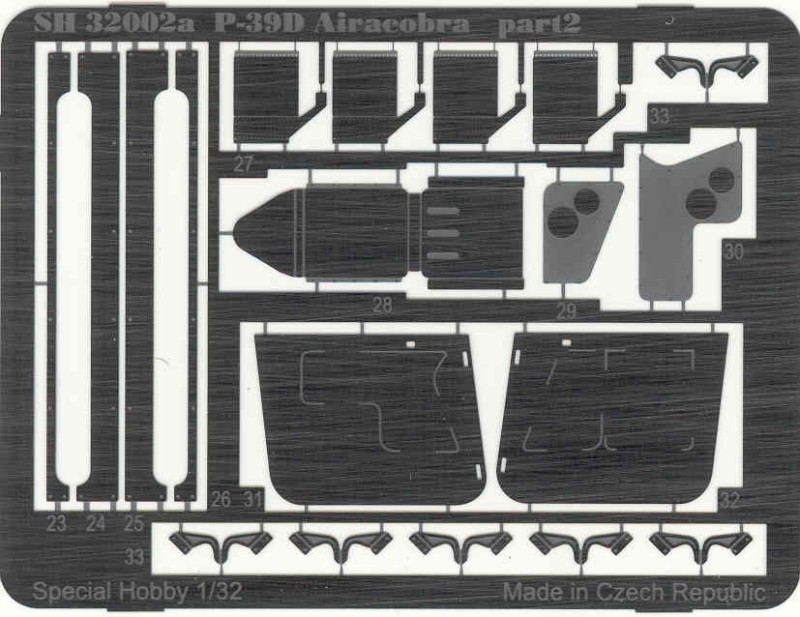

The Special Hobby kit comes in a fairly large top open tray type box with a thin top and the bottom made from thin corrugated cardboard providing a solid box. Inside there I one large resealable bag with all of the main parts in it. The clear parts are in a separate resealable bag and the resin in a small zip lock bag. The decals and photo etch frets are in a resealable sleeve. The parts are molded in a medium gray plastic and exhibit a light amount of flash. The parts are well molded for low pressure molded parts and the mold separation seams are moderate. Ejector pin marks and towers appear to have been kept out of visible areas. The surface detail consists of fine engraved panel line with engraved rivets and fasteners. One can even see slots in the heads of some of the fasteners. Raised detail is also used where appropriate. The panel lines are all consistent. I found no surface defects on any of the air frame parts. There were some small sink marks near the root of the propeller blades on the back side.

From

a detail standpoint, the control surfaces, except for the flaps are

all

separate, fabric detail represented by rib tapes only. The cockpit is

well appointed and mounts atop the nose wheel bay as part of the

assembly. The nose wheel bay is made up of a number of parts that

provide side wall and end detail as well as the top and a bulkhead.

The

cockpit floor makes up part of the top of the wheel bay. Fourteen

pieces go into the cockpit not counting the seat and the PE belts and

harness which has separate buckles. The area behind the pilot includes

a radio set. The instrument panel is nicely done with raised dials and

switches an the dials have internal detail. Inside the wings are

parts that make up the cooling and radiator ducting and parts that

close in the main wheel bays. The nose cannon which passes through the

nose wheel bay is included and the nose wheel assembly it self looks

quite complete. The inside panels of the cockpit doors are made up of

no less than 17 photo etched parts, some of which were not included

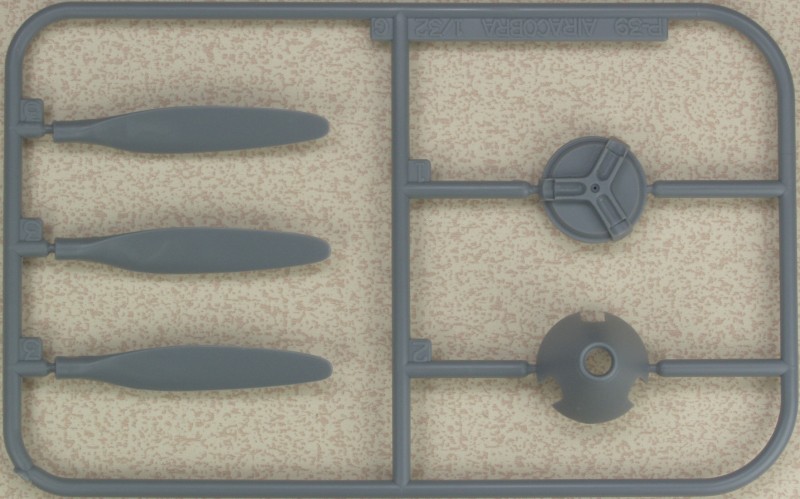

with my kit. More on that later. The propeller is a multi part affair

with separate blades which are keyed for the pitch. The wheels come in

halves with separate inside and outside hubs. The tires are not

weighted.

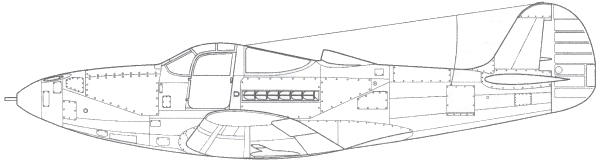

I normally don't spend much time on accuracy but this kit has generated a lot of discussion concerning the fuselage length. Most of the egg spurts have decided that the length of the fuselage between the rear of the cockpit and the tail is a bit short. This discrepancy amounts to something in the neighborhood of 3/16" to 1/4" or about 6 to 8 scale inches. I have seen photos of kits with the fuselage extended by this amount and unless it is sitting side by side with one that hasn't it is not all that noticeable. When Kitty Hawk released their kit the hope was that they would fix this issue as it was well known but in the end the Kitty Hawk kit came up short as well and had a lot of other issues like poorly fitting separate inspection panels that only worked in the open position. I mention this in case you are obsessed with highly accurate dimensions. To me, kits built without the extension look just fine to my eye. With this out of the way lets look at the parts.

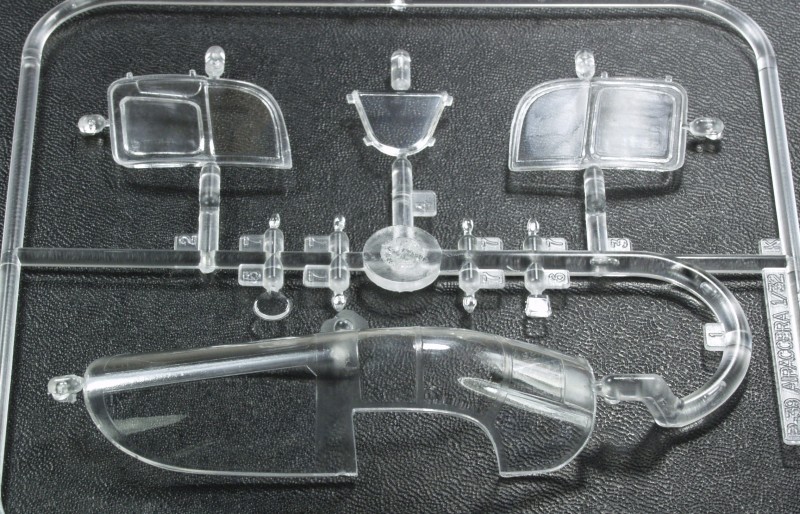

The clear parts are reasonably clear with a little optical distortion. The doors are molded one piece with the side glazings eliminating one place where fit problems could occur.

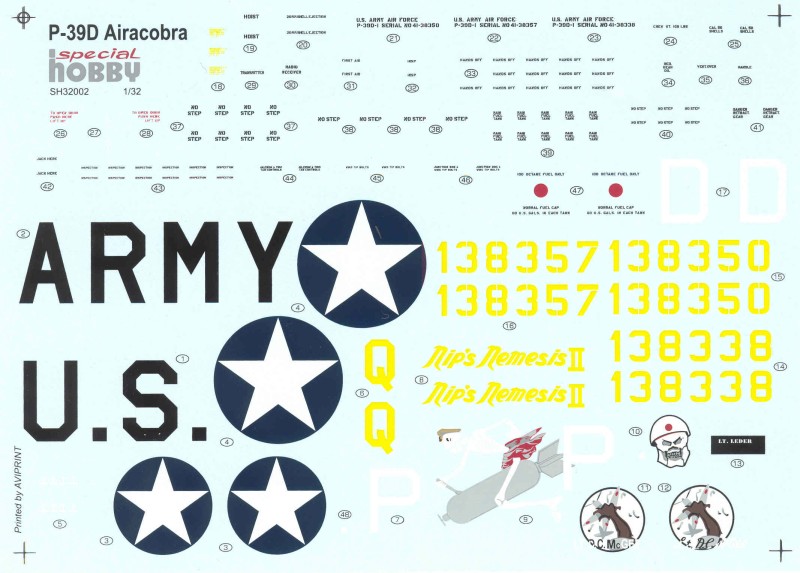

The decals are thin and in register. It's difficult to tell but the white letters and yellow numbers may not be fully opaque. They are printed by Aviprint and I have had good luck with them in the past. I suspect that the U.S. Army markings should be insignia blue instead of black so check you references. The sheet provided marking for three aircraft; 35th FS, 8th Fighter Group, Pilot Lt,I.A. Erickson, Milne Bay, New Guinea, 1942; 35th FS, 8th Fighter Group, pilot Lt. Leder, Milne Bay, New Guinea, October, 1942; 36th FS, 8th Fighter Group, pilot Lt. Donald C. McGee, Seven Mile Strip airfield, Port Moresby, New Guinea, June, 1942.

The instructions are a little better than what are found in a lot of Special Hobby kits. It's a A4 size 12 page booklet, not stapled. It features all the standard stuff, history and specifications, a parts map. icon chart, and a paint chart with Gunze numbers. Nine pages are dedicated to assembly diagrams with the assembly divided into 29 steps. The main difference here is the larger size which allows for the assembly diagrams to be larger and more detailed. The back page is a catalog of sorts of their other 1/32 scale kits. Painting and marking information is supplied on a separate sheet printed in color on glossy paper about the same size as their instruction sheet in other kits. One page of it has locations for the stencils of which quite a few are provided.

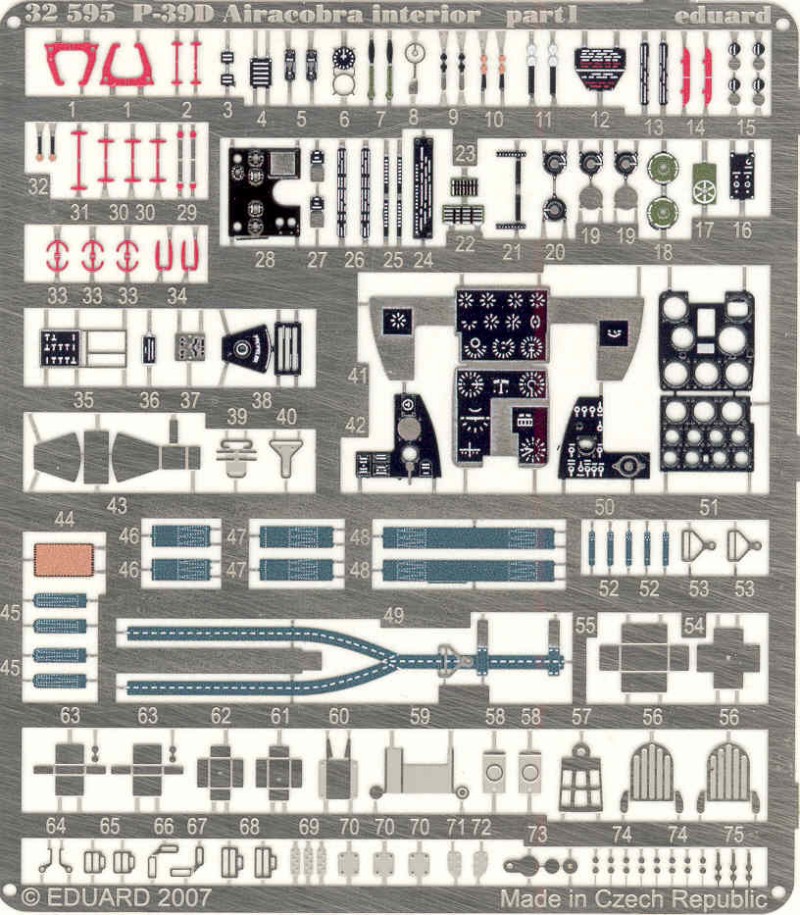

After Market Goodies

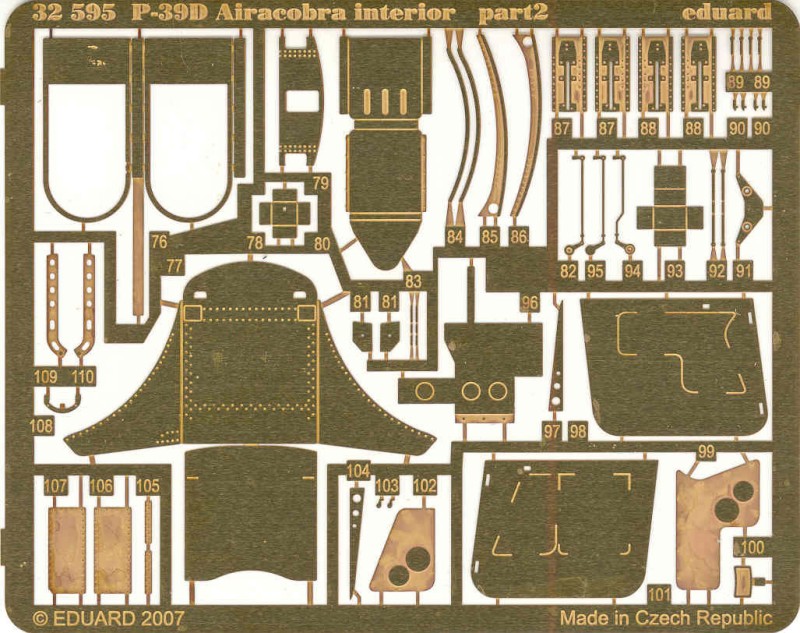

The Eduard photo etch set (32595) was acquired in hopes that some of the parts that were missing from the kit fret will be included and I wanted the color instrument panel as I suck when it comes to painting them. From the looks of things I got what I wanted and a whole lot more.

Conclusions

Special Hobby, like some of the other makers of short run low pressure molded kits, have made great strides in the quality and level of detail provided in their kits over the past few years and it seems like each one gets a bit better. The quality of this kit, while not what you would get in a Tamiya or Hasegawa kit, is very nice and should produce a very nice finished product. It is none the less a limited run kit and that means doing a lot of test fitting before gluing and some fit issues are to be expected. If the length of the fuselage is a problem for you the only option is to cut and splice the fuselage. I don't plan on doing this as I think it looks OK as it is. I think any modeler with a bit of experience with limited run kits would have little trouble with this one. Recommended.

Links to kit build or reviews

Another in box review can be found here and a build / review here.

References

Bell P-39 Airacobra by Artur Juszczak and Robert Peczkowski

Back to the 1/32 U.S. Aircraft Page