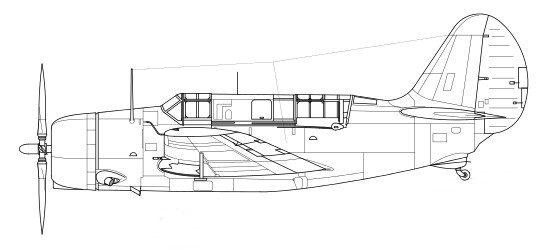

Curtiss SB2C-4

The Helldiver

was developed to replace the Douglas SBD Dauntless. It was a much larger

aircraft, able to operate from the latest aircraft carriers and carry a

considerable array of armament. It featured an internal bomb bay that

reduced drag when carrying heavy ordnance. Saddled with demanding

requirements set forth by both the U.S. Marines and United States Army Air

Forces, the manufacturer incorporated features of a "multi-role" aircraft

into the design.

The Model

XSB2C-1 prototype initially suffered teething problems connected to its

Wright R-2600 Twin Cyclone engine and three-bladed propeller;

further concerns included structural weaknesses, poor handling,

directional instability, and bad stall

characteristics. The first prototype made its maiden flight on 18 December

1940. It crashed on 8 February 1941 when its engine failed on approach,

but Curtiss was asked to rebuild it.

The fuselage

was lengthened and a larger tail was fitted, while an autopilot was fitted

to help the poor stability. The revised prototype flew again on 20 October

1941, but was destroyed when its wing failed during diving tests on 21

December 1941. Large-scale production had already been ordered on 29

November 1940, but a large number of modifications were specified for the

production model. Fin and rudder area were increased, fuel capacity was

increased, self-sealing fuel tanks were added, and the fixed armament was

doubled to four 0.50 in (12.7 mm) machine guns in the wings,

compared with the prototype's two cowling guns. The SB2C-1 was built with

larger fuel tanks, improving its range considerably.

The program

suffered so many delays that the Grumman TBF Avenger entered service

before the Helldiver, even though the Avenger had begun its development

two years later. Nevertheless, production tempo accelerated with

production at Columbus, Ohio and two Canadian factories: Fairchild

Aircraft Ltd. (Canada), which produced 300 (under the

designations XSBF-l, SBF-l, SBF-3, and SBF-4E), and Canadian Car and

Foundry, which built 894 (designated SBW-l, SBW-3, SBW-4, SBW-4E, and

SBW-5), these models being respectively equivalent to their Curtiss-built

counterparts. A total of 7,140 SB2Cs were produced in World War II.

Among its major

faults, the Helldiver was underpowered, had a shorter range than the SBD,

was equipped with an unreliable electrical system, and was often poorly

manufactured. The Curtiss-Electric propeller and the complex hydraulic

system had frequent maintenance problems. One of the faults remaining with

the aircraft through its operational life was poor longitudinal stability,

resulting from a fuselage that was too short due to the necessity of

fitting onto aircraft carrier elevators The Helldiver's aileron response

was also poor and handling suffered greatly under 100 mph airspeed;

since the speed of approach to land on a carrier was supposed to be

98 mph, this proved problematic. The 880 changes demanded by the Navy

and modification of the aircraft to its combat role resulted in a 42%

weight increase, explaining much of the problem.

The solution to these problems began with the introduction of the SB2C-3

beginning in 1944, which used the R-2600-20 Twin Cyclone engine with

1,900 hp and Curtiss' four-bladed

propeller. This substantially solved the chronic lack of power that had

plagued the aircraft. The Helldivers would participate in battles over the

Marianas, Philippines (partly responsible for sinking the battleship Musashi),

Taiwan, Iwo Jima, and Okinawa (in the sinking of the battleship Yamato).

They were also used in the 1945 attacks on the Ryukyu Islands and the

Japanese home island of Honshū in

tactical attacks on airfields, communications and shipping. They were also

used extensively in patrols during the period between the dropping of the

atomic bombs and the official Japanese

surrender, and in the immediate pre-occupation period.

In operational

experience, it was found that the U.S. Navy's Grumman F6F Hellcat and

Vought F4U Corsair fighters were able to carry an equally heavy bomb load

against ground targets and were vastly more capable of defending

themselves against enemy fighters. The Helldiver, however, could still

deliver ordnance with more precision against specific targets and its

two-seat configuration permitted a second set of eyes. A Helldiver also

has a significant advantage in range over a fighter while carrying a bomb

load, which is extremely important in naval operations. The advent of

air-to-ground rockets ensured that the SB2C was the last purpose-built

dive bomber produced. Rockets allowed precision attack against surface

naval and land targets, while avoiding the stresses of near-vertical dives

and the demanding performance requirements that they placed on dive

bombers.

The SB2C

remained in active postwar service in active duty US Navy squadrons until

1947 and in Naval Reserve aviation units until 1950. Surplus aircraft were

sold to the naval air forces of France, Italy, Greece, Portugal, and

Thailand. Greek SB2Cs served in combat in the Greek Civil War with

additional machine guns mounted in wing pods. French SB2Cs flew in the

First Indochina War from 1951 to 1954.

The

Kit

Infinity Models

is a new name in the world of aircraft models and this is their first kit.

The name may be new but the company behind it is not. HPH models is a

Czech company that has been making high quality resin kits for a number of

years and in fact produced a resin kit of this same aircraft a couple

years ago. They tended to build kits of significant aircraft that have

been ignored in 1/32 scale by the main stream kit makers. At some point

they decided they would have a larger audience if they produced injection

molded kits and this is their attempt. HPH is still making resin and

fiberglass kits of very large aircraft in 1/32 that would have limited

appeal to most modelers and the name Infinity identifies their injection

molded kits. So lets take a look and see how they did.

The kit comes

in an appropriately sized box, a top open tray style box with a thin card

stock top and a thin corrugated bottom. As shown above the box top artwork

is quite nice. Inside the box are 8 resealable plastic bags containing the

parts molded in a blue gray color, 1 bag with the clear parts and a bag

with the decals, seat harnesses and belts and a photo etch fret with the

hardware for the harnesses and a gun sight. A statement in the

introduction on the front of the instructions says "Plastic model kit is

produced be 'short run' technology for experienced modelers." At one time

the 'short run' meant poor molding, grainy surface texture, tons of flash

and poor fitting parts. That has changed greatly over the past few years

with many short run kits coming very close in quality the main stream

kits. Lets take a look...

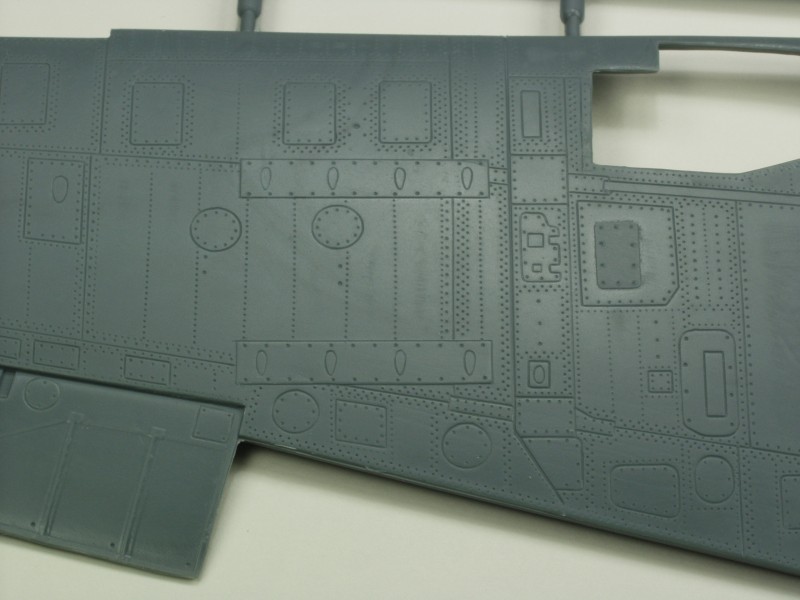

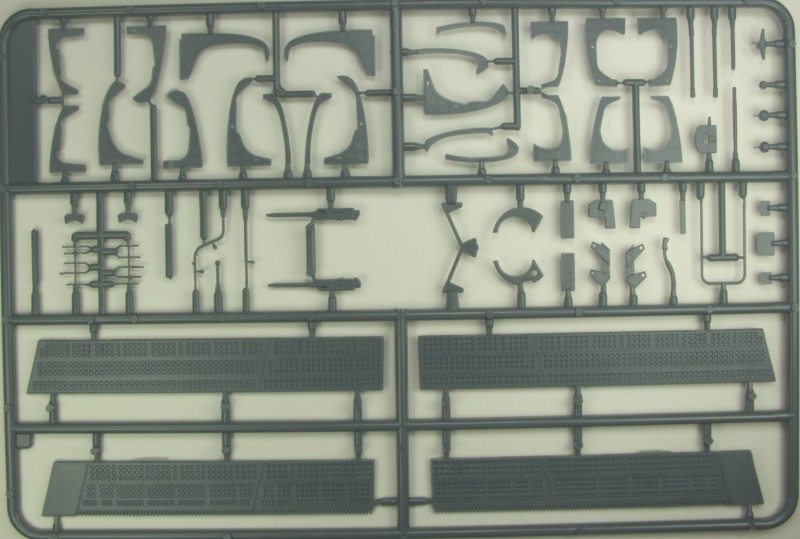

First up is

sprue 'B'. Note: a parts map is included in the instructions with sprue

letters and part numbers but neither are marked on the sprues themselves

with a couple exceptions where the sprue letter is on the sprue. Sprue 'B'

has the starboard fuselage and upper wing half. There is some light flash

to be found and the sprue attachment points tend to overlap the mating

surface. The surface detail consists of recessed rivets, fasteners and

panel lines. The rivets and panel lines are quite fine and uniform but

some care will need to taken when painting as they may tend to disappear

under a heavy coat of paint. The rudder and ailerons are molded in a

neutral position, the leading edge slats, flaps and dive brakes are

separate pieces. The rudder hinge line is a little shallow for my taste

and I suspect many with AMS will cut the rudder off so they can pose it in

a different position. The fabric portion of the rudder is represented with

rib tapes and stitching which again is quite fine. For those who think

they can't live without them, not of the parts have alignment pins. I did

not find any surface aberrations on the fuselage or upper wing

halves. I did not photograph sprue 'A' as it looks identical with

the port fuselage and upper wing half.

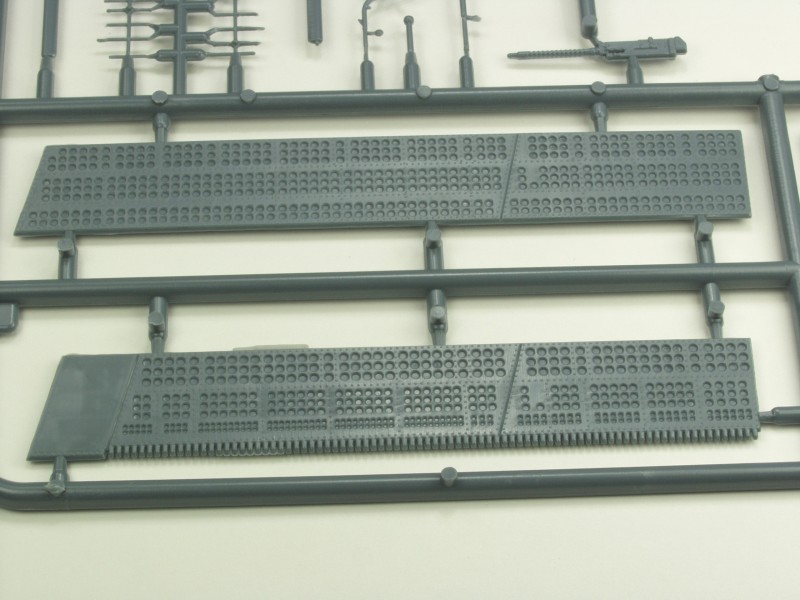

The next photo

shows a close up of the surface detail on the wing which is very nice for

a short run kit. It also shows the internal structure detail of the

fuselage and to their credit there are only two ejector pin marks in the

whole area that might show and they look easy enough to remove assuming

they don't get hidden by other detail.

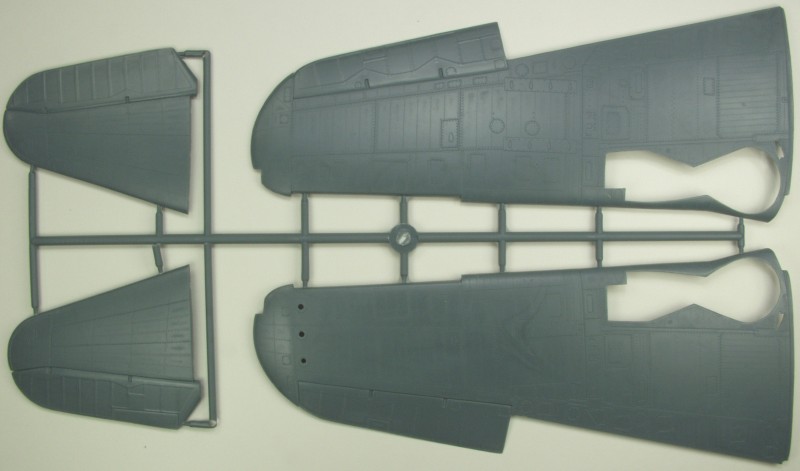

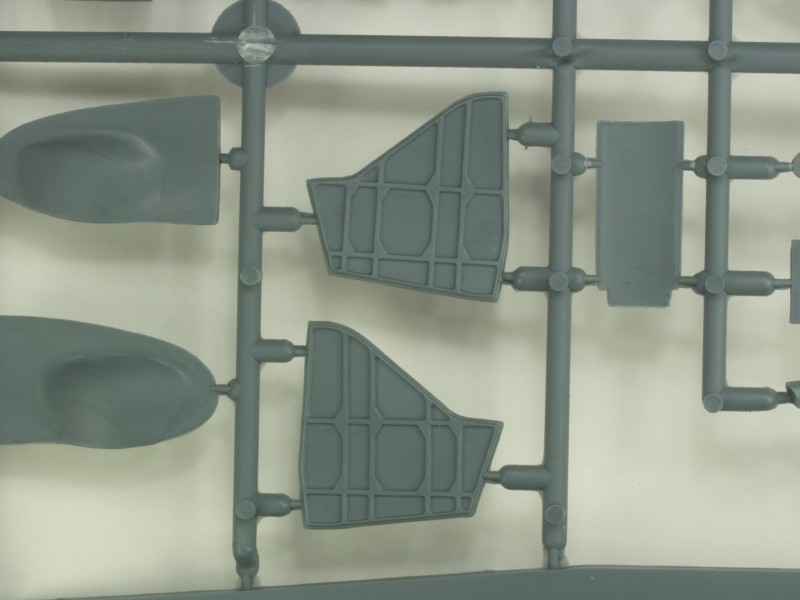

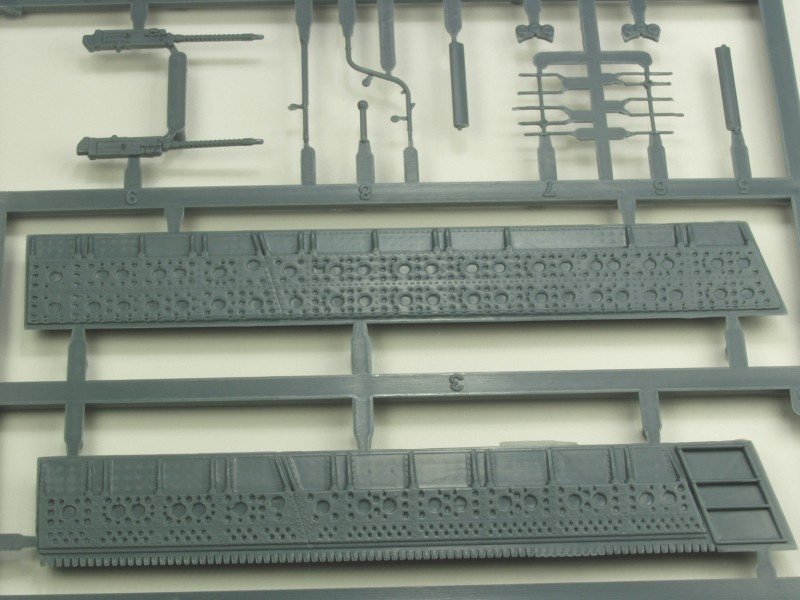

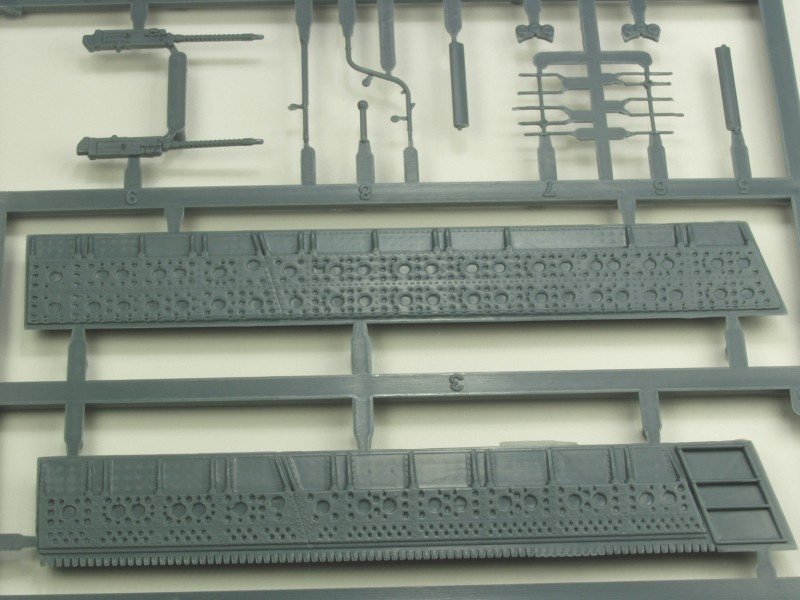

Sprue 'H' is

next with the top halves of the horizontal stabilizers and the bottom wing

halves. Surface wise these are the same as the other pieces reviewed

above. The hinge lines on the elevators is better than those on the rudder

and again are molded in the neutral position.

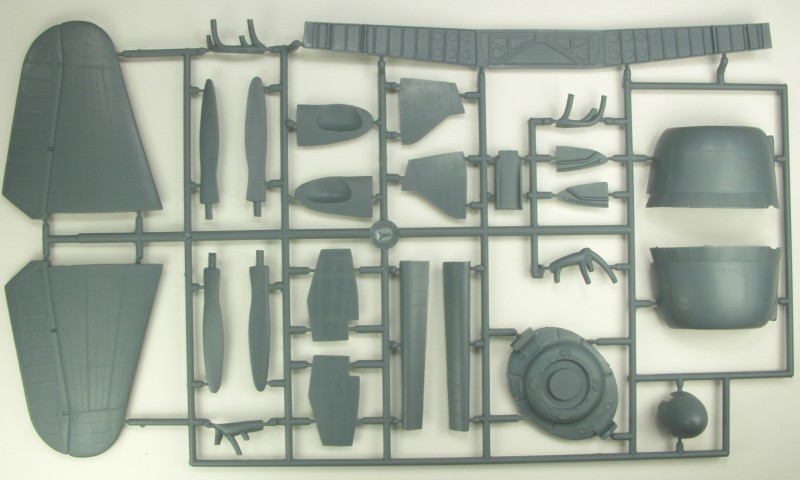

Next is sprue

'I' which has the lower horizontal stabilizers, wing spar, prop blades,

engine mounting bulkhead, cowling, exhaust pipes and spinner. also on the

sprue are landing gear doors.

They also

managed to avoid ejector pin marks on the back sides of the gear doors.

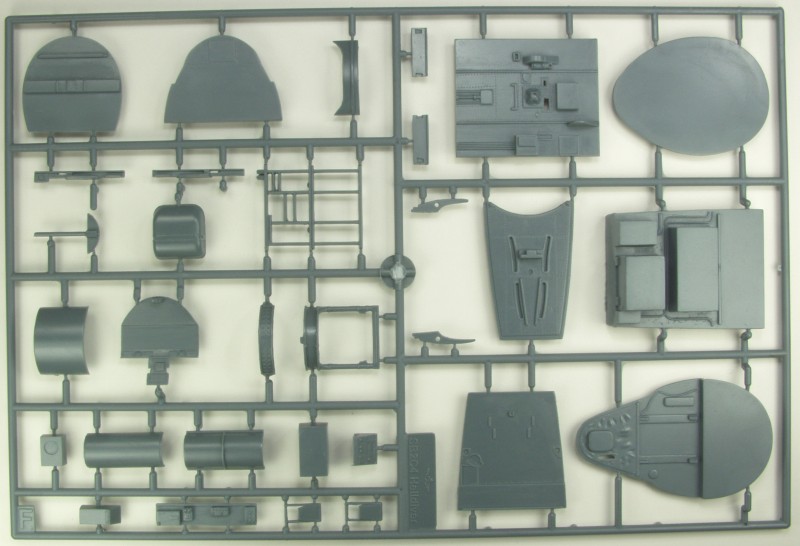

Sprue 'F' is

one of the few actually identified on the sprue itself and contains most

cockpit parts. The cockpit and interior is pretty well detailed right out

of the box as will be illustrated later in the instruction manual section.

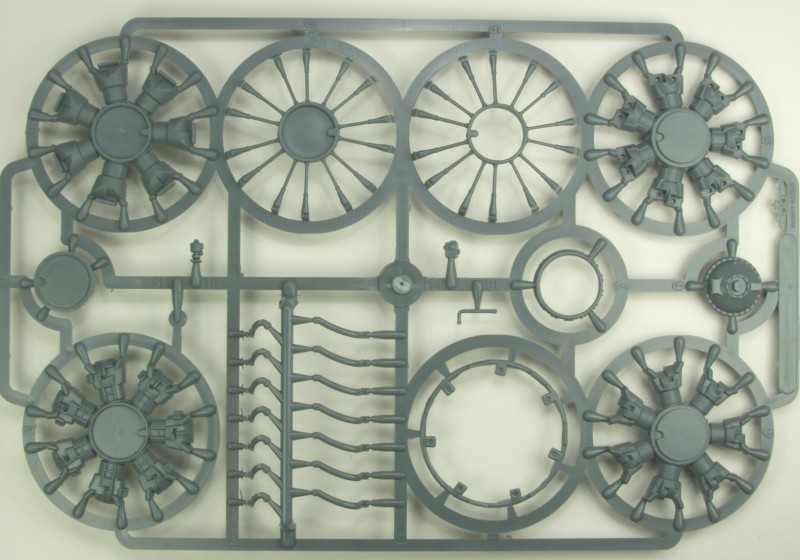

Sprue 'E' is

all engine parts and with the addition of some wiring should look quite

nice considering the tight cowling.

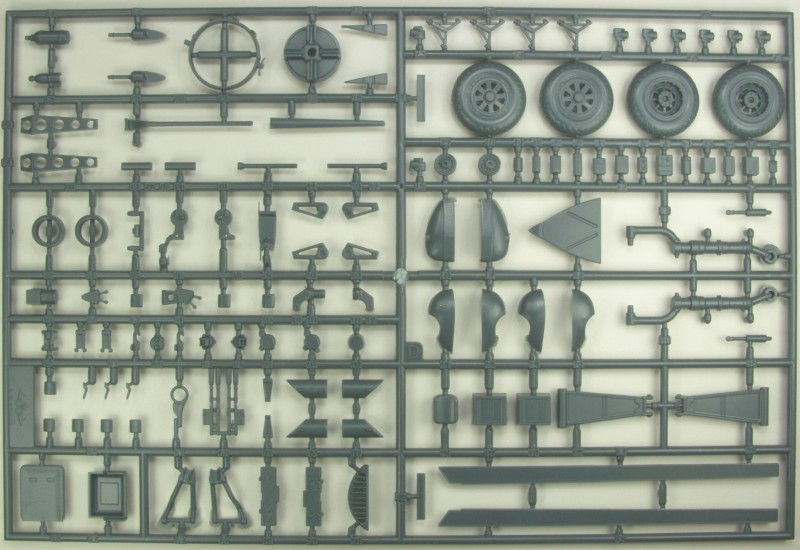

Sprue 'D' is

another one actually marked and it also has the part number molded in as

well which is really helpful as there are a ton of detail parts on this

sprue, the wheels, molded in halves and not weighted. Many of these parts

are for the interior detail. One place where the short run aspect is more

apparent is on the small detail parts, they have more flash and mold

alignment seams to clean up and a few of the smaller parts are not as

sharply molded as they would be in a main stream kit.

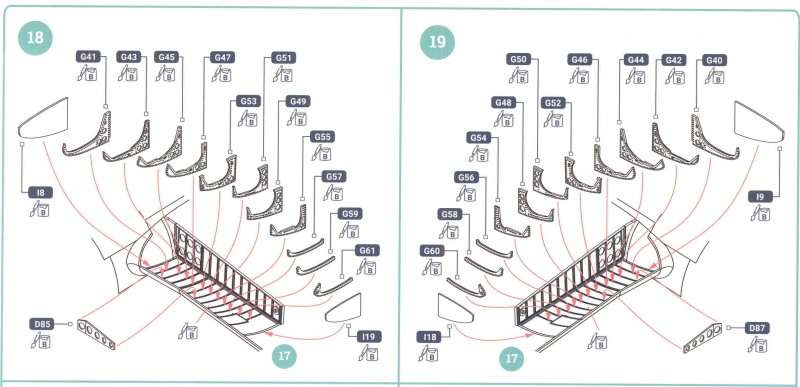

Sprue 'G' also

has the sprue and part numbers molded in again helpful as many parts are

very similar. The bulkheads for the gear bays are another place where the

lightening holes should be drilled out. A few additional detailing parts

and guns for the gunners station are on this sprue. Also included are the

dive breaks and flaps.

Close ups of

the dive brakes and flaps. If you want the holes open, you are in for a

lot of drilling. More on that later.

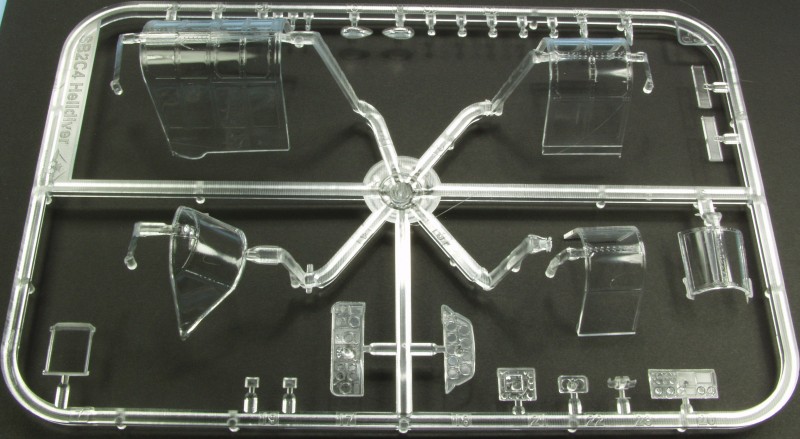

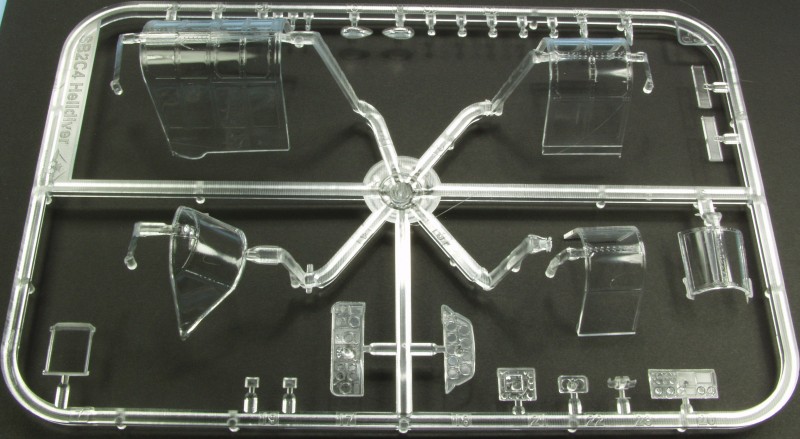

The

clear

parts are quite clear, reasonably thin and have very little

optical distortion. The frame lines are raised and well defined

to make masking easy. Besides the canopies there are navigation

light lenses, formation light lenses and clear instrument panels

which are intended to be used with instrument decals that are

supplied.

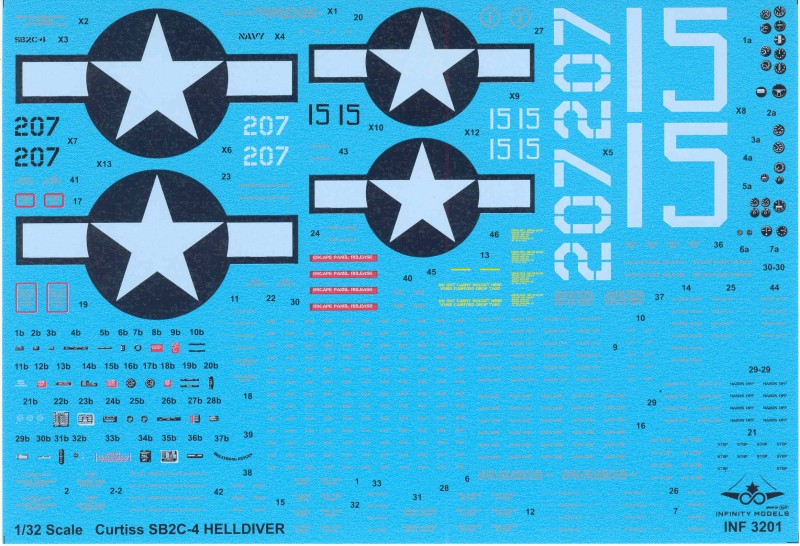

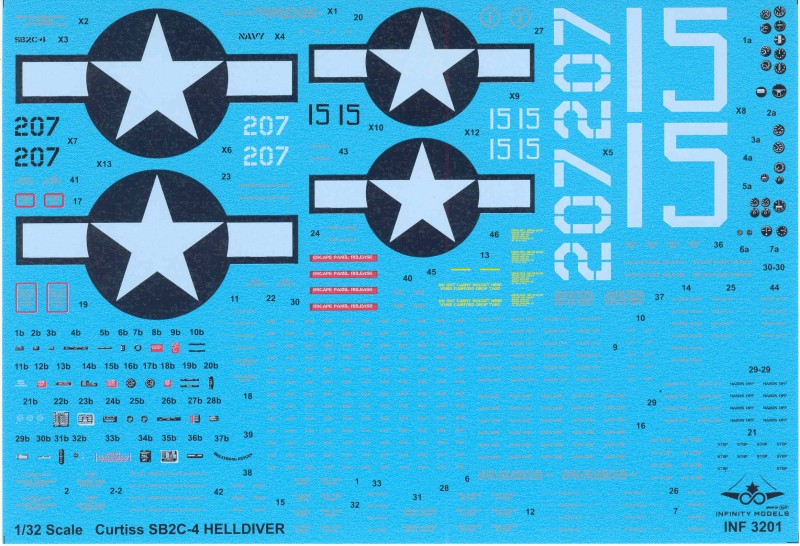

The

decals include markings for two aircraft, one from VB-83 from

the USS Essex, April 1945 and the other from VB-12 from the USS

Randolph, February 1945. The first on is in the tricolor scheme

and the second in the overall blue scheme. There are no

manufacture names on the decals so not sure who did them. The

larger markings are all in register but many of the smaller ones

are not such as the instrument dials and some of the placards.

There are a bunch of stencils, many of them difficult to read on

sheet because of their light color. They should be readable on a

dark surface. The decals are glossy and it's difficult to tell

how opaque the white will be when placed on a dark surface.

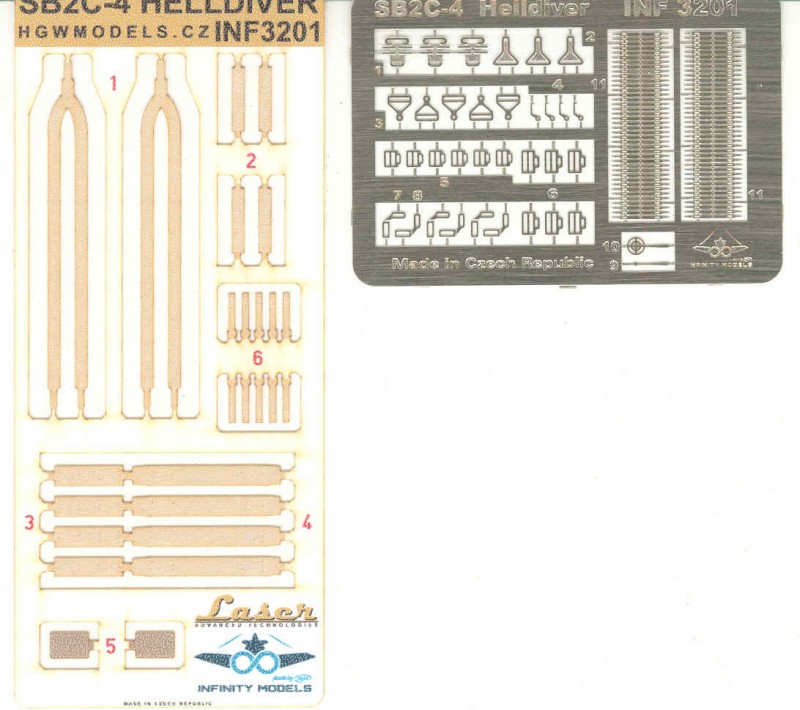

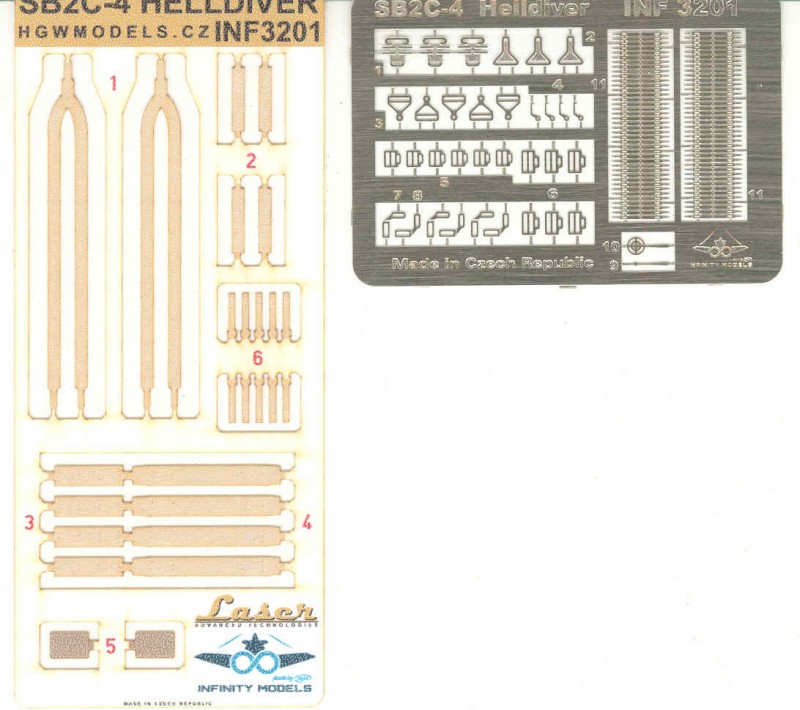

The kit

includes a set of HGW laser cut harnesses and belts. I'm not sure if these

are a type of paper or microfiber but they are precolored. A photo etched

fret with the hardware for the harnesses is included which also has and

gun sight and ammo belts.

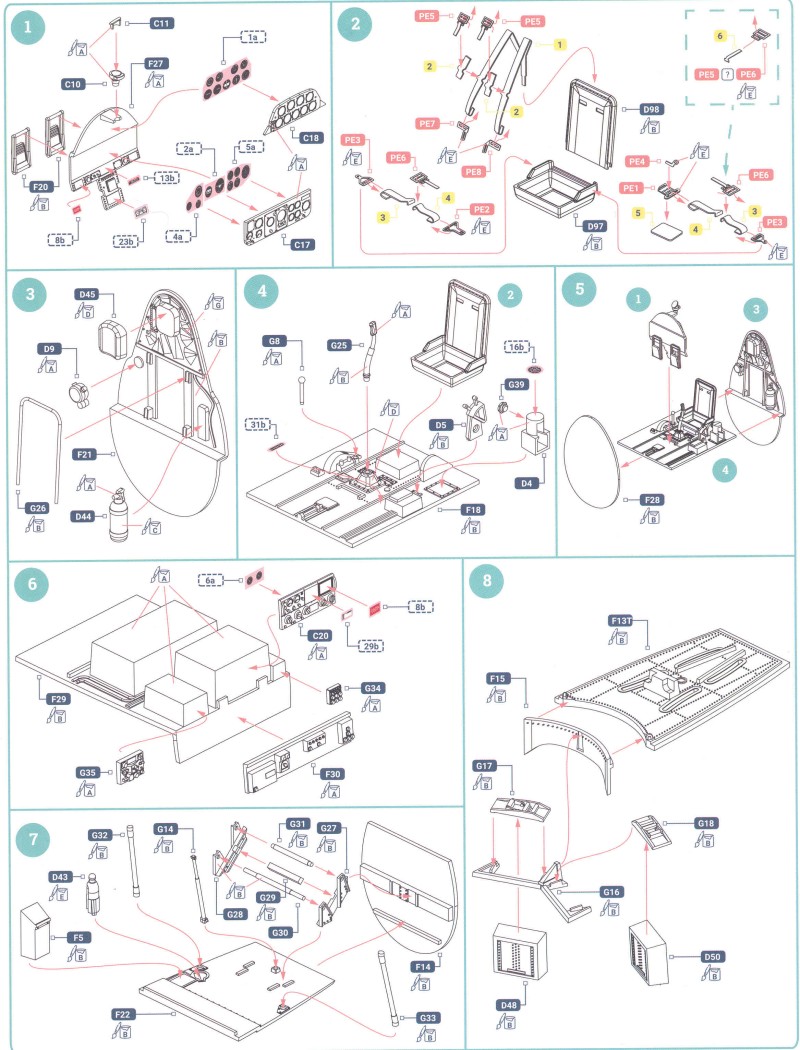

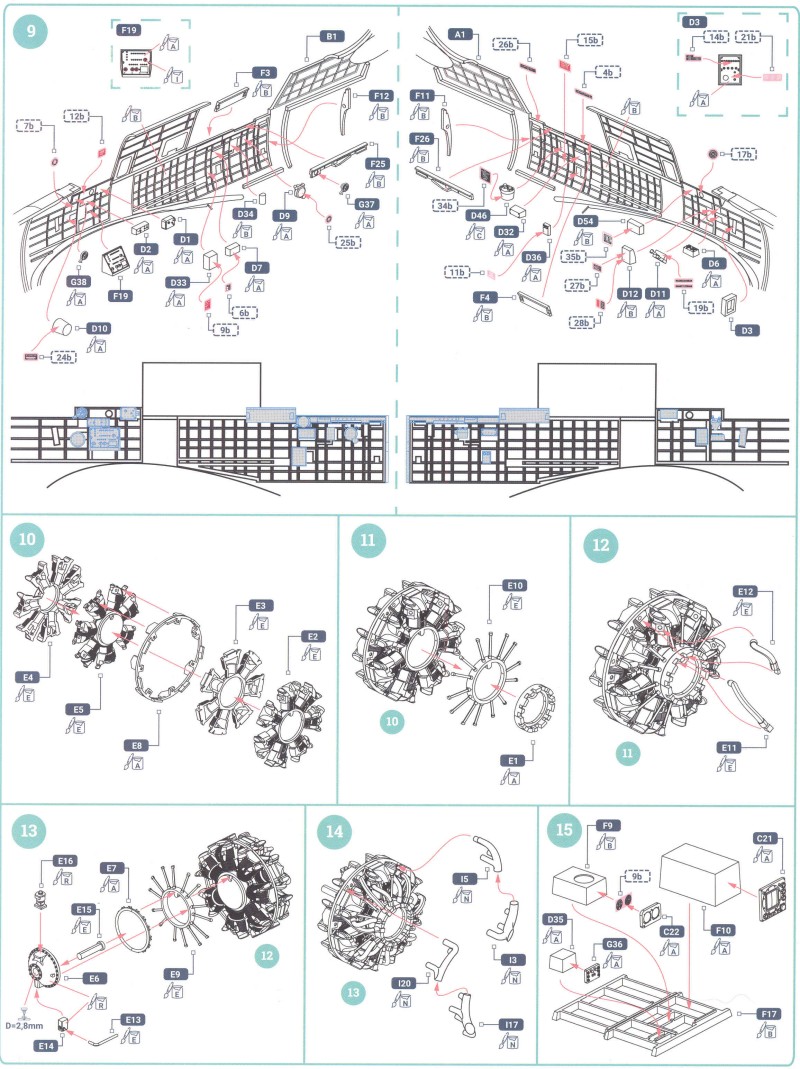

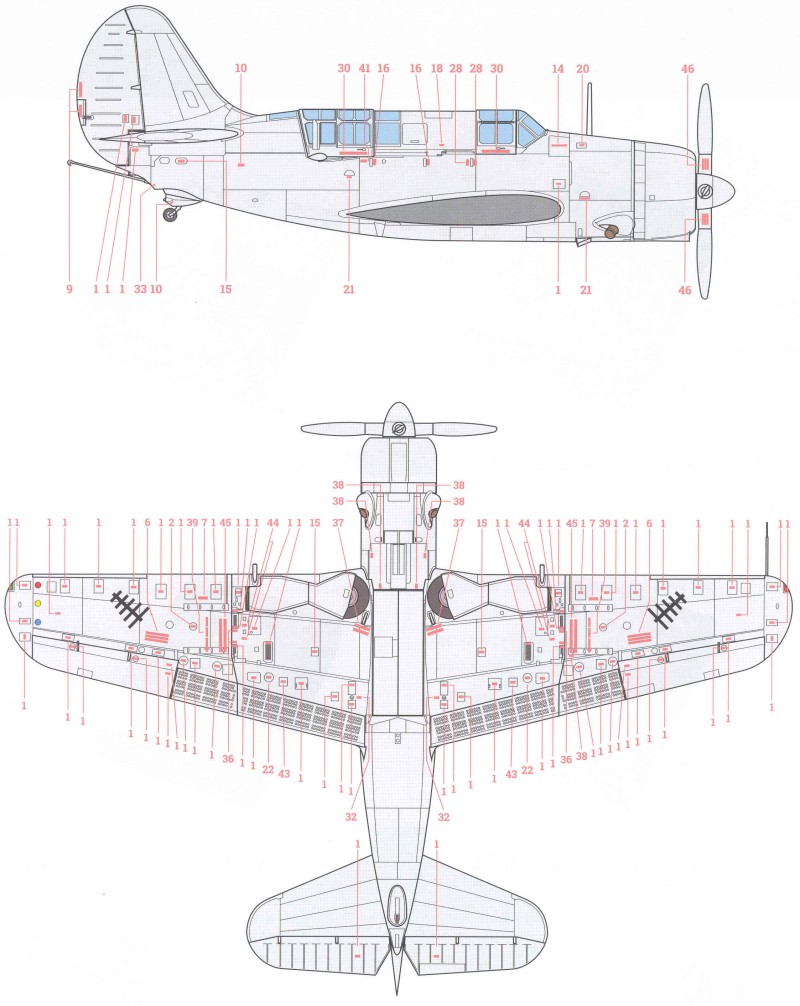

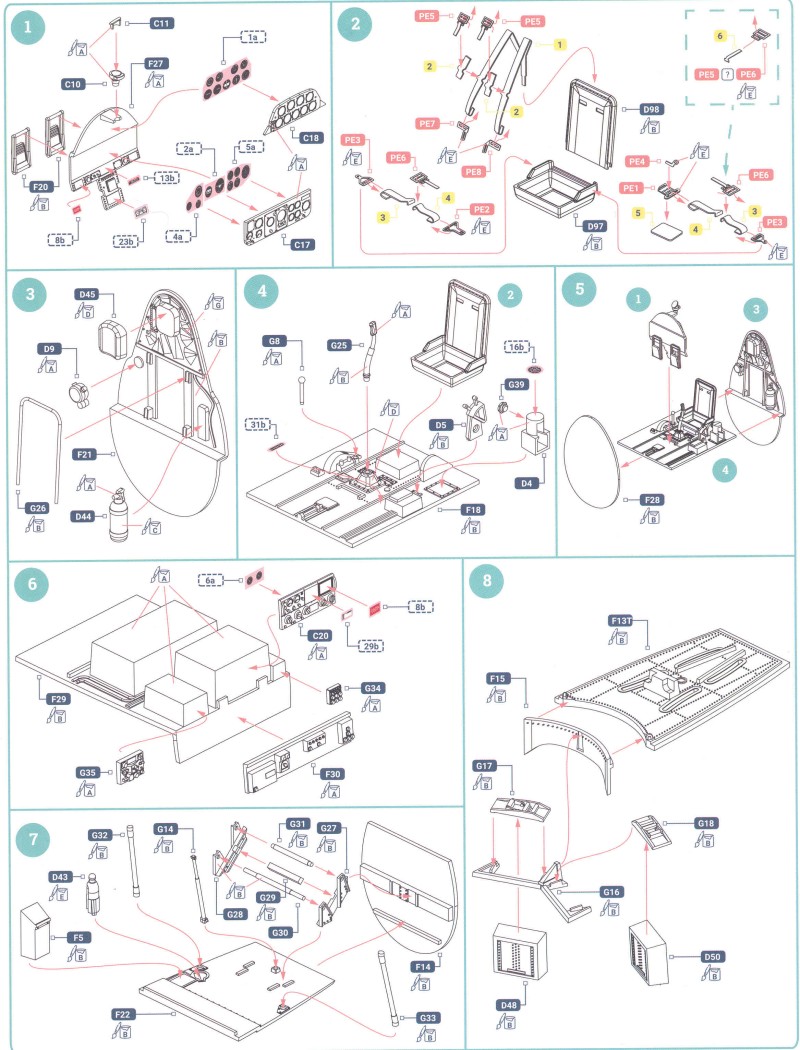

The

instructions are a 16 page booklet, color printed

on glossy paper and stapled at the spine. I've

included a few sample pages to give an idea of the

detail level of the interior. As can be seen the

cockpit and fuselage interior are amply detailed.

Some of the diagrams like step 9 are a little bit

busy so one will need to take care during

assembly.

The gear bays

feature a good amount of detail.

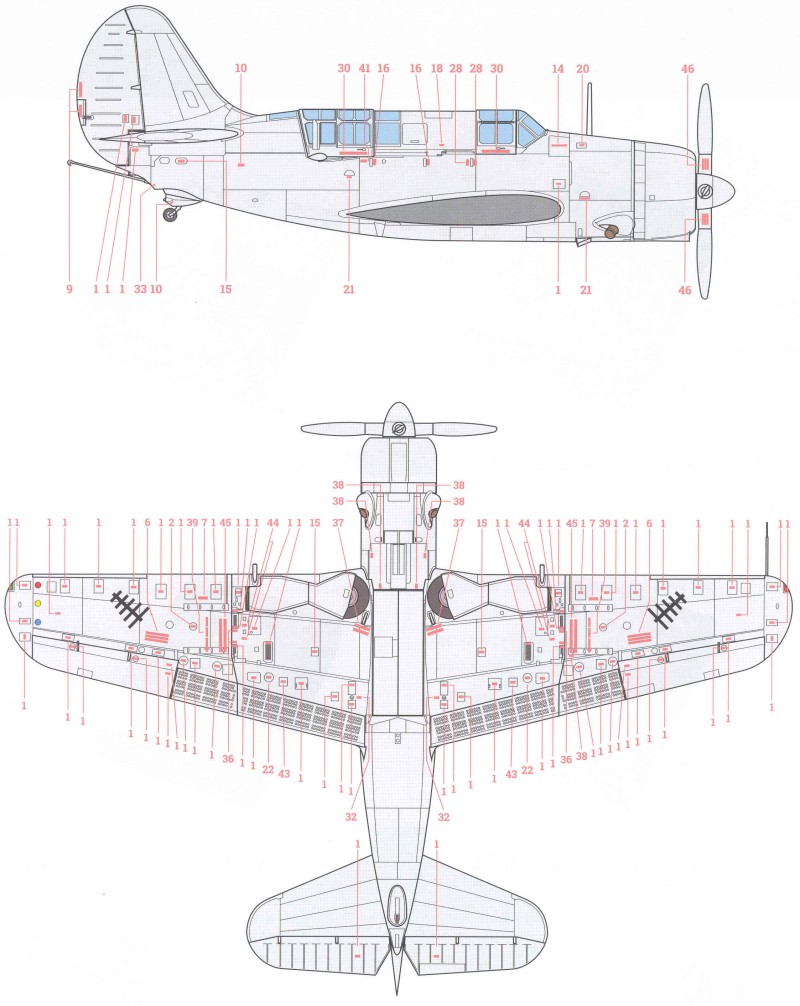

As you can see

from the decal placement guide you get a bunch of stencil decals to apply,

the top side of the wing gets almost as many as the bottom.

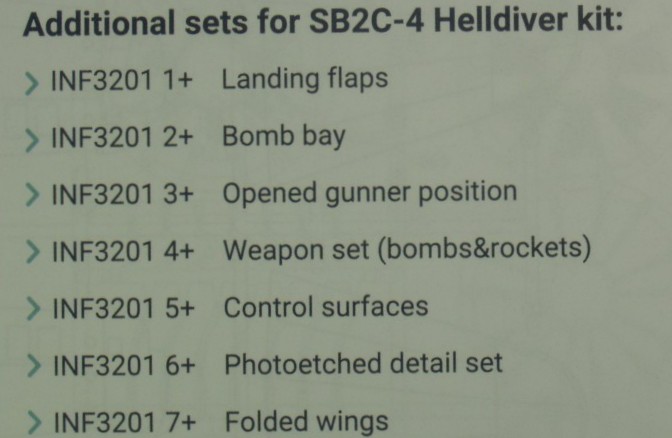

After

Market

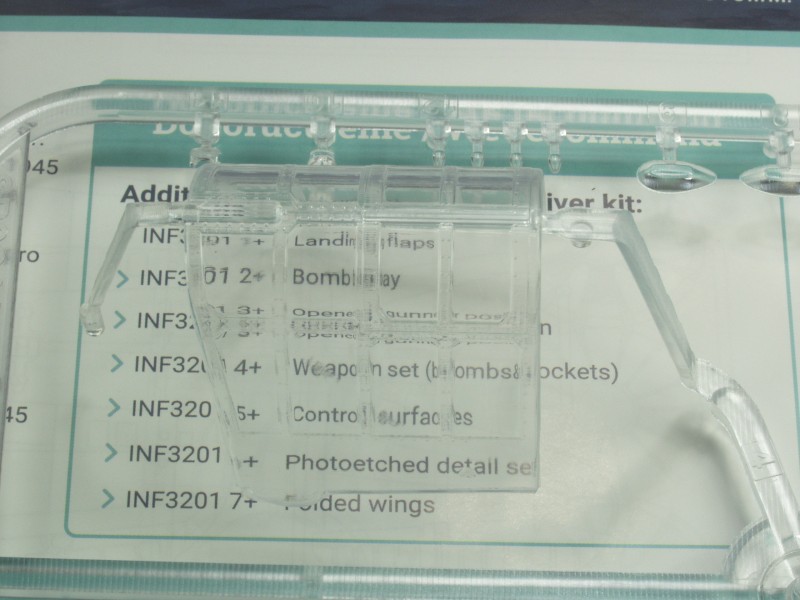

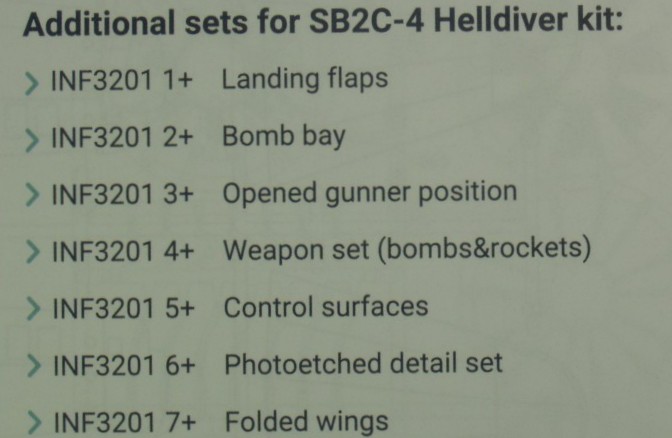

Goodies

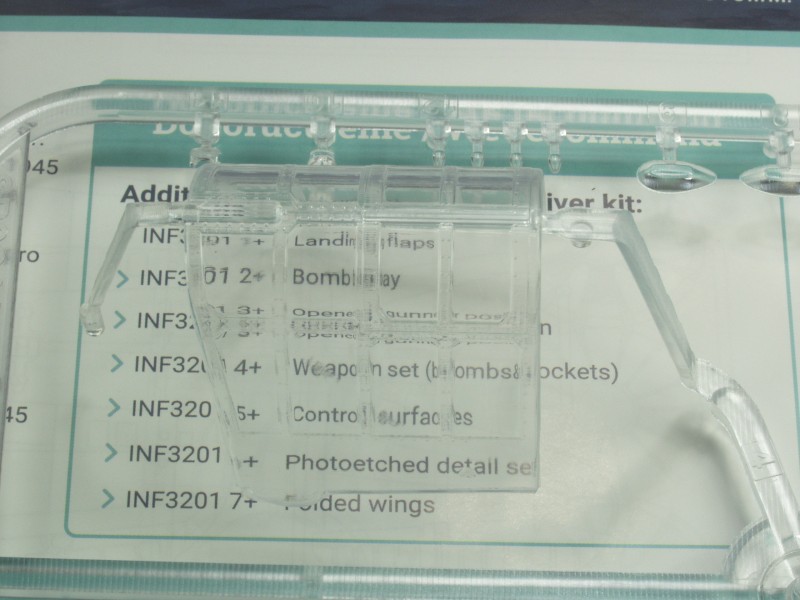

Like a number of other manufacturers

Infinity is offering their own detailing sets rather than

waiting for after market companies. At the time of this review I

don't think all of the sets are available yet. I haven't seen

the price either but I suspect if you get them all it will

easily double the price of the kit.

Conclusions

Like many short run kits this one looks

good in the box, only time will tell how well every thing fits

together. Just don't be too surprised if it doesn't go together

like a Tamiya or Hasegawa kit. I applaud their choice of subject

and it should sell well at least in the US and possibly some of

the countries that operated it post war. Their next two kits in

development are a D3A Val and a DH-100 Vampire Mk 5 and I'm very

much looking forward to them as well.

Links

to kit build or reviews

References

Wikipedia

Back to the 1/32 US Aircraft page

Updated 5/13/21