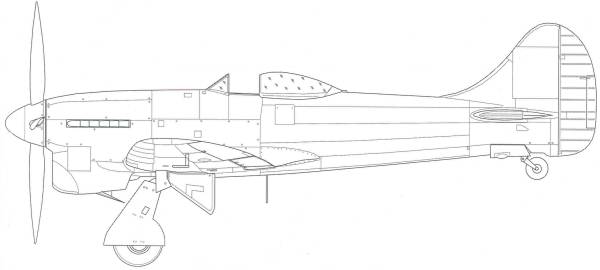

Hawker

Tempest Series II Mk.Vc

During development of the Typhoon the design team, under the leadership of Sydney Camm, were already planning design improvements, this process resulting in the Hawker P. 1012 (or Typhoon II).Although the Typhoon was generally a good design, Camm and his design team were disappointed with the wing, which proved to be too thick in its cross section. This created airflow problems and inhibited flight performance, especially at higher altitudes and speeds. In March 1940, engineers were assigned to investigate the new low drag laminar flow wing developed by NACA in the United States, which had been used in the new P-51 Mustang.

The wingspan was originally greater than that of the Typhoon at 43 ft, but the wingtips were later "clipped" and the wing became shorter; 41 ft versus 41 ft 7 in. The wing plan form was changed to an elliptical shape to accommodate the 800 rounds of ammunition for the four 20 mm Hispano cannons, which were moved back further into the wing. The new elliptical wing had greater area than the Typhoon's. However, the new wing design sacrificed the leading edge fuel tanks of the Typhoon. To make up for this loss in capacity, Hawker engineers added a new 21 in fuel bay in front of the cockpit, with a 76 gallon fuel tank. In addition, two inter-spar wing tanks, each of 28 gallon, were fitted on either side of the center-section and, starting with late model Tempest Vs, a 30 gallon tank was carried in the leading edge of the port wing root, giving the Tempest a total internal fuel capacity of 162 gallons.

In service, Tempests also carried two specially designed, streamlined, drop tanks of 45 gallons giving a maximum of 360 gallons and an operational radius of 500 miles. A further improvement of the Tempest wing over that of the Typhoon was the exceptional, flush riveted surface finish, essential on a high performance laminar flow airfoil. Fortunately for the pilots, the new wing and airfoil, and the four-bladed propeller unit, eliminated the high frequency vibrations that had plagued the Typhoon.

The redesigned main undercarriage legs were longer and had a wider track to improve stability at the high landing speed of 110 mph, and to allow tip clearance for a new De Havilland 14 ft diameter four-blade propeller. The main undercarriage units were Dowty levered suspension units incorporating trunnions which shortened the legs as they retracted. The majority of the Tempests built used 30 by 9 inch four-spoke wheels, while the prototypes and early production Tempest Vs used the Typhoon's larger 34 by 11 inch five-spoke wheels. The retractable tail wheel was fully enclosed by small doors and could be fitted with either a plain Dunlop manufactured tire, or a Dunlop-Marstrand "twin-contact" anti-shimmy tire.

Camm and the Hawker design team placed a high priority on making their aircraft easily accessible to both air and ground crews; to this end the forward fuselage and cockpit areas of the earlier Hurricane and the Tempest and Typhoon families were covered by large removable panels providing access to as many components as possible, including flight controls and engine accessories. Both upper wing roots incorporated panels of non-slip coating. For the pilot a retractable foot stirrup under the starboard root trailing edge was linked to a pair of hand holds which were covered by spring-loaded flaps. Through a system of linkages, when the canopy was open the stirrup was lowered and the flaps opened, providing easy access to the cockpit. As the canopy was closed the stirrup was raised into the fuselage and the flaps snapped shut.

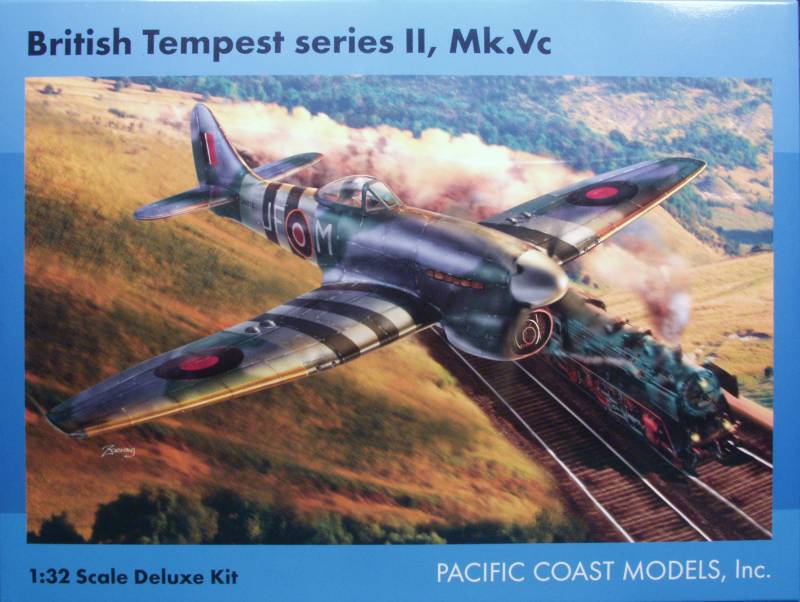

The Kit

The Pacific Coast Models kit comes in a large top open tray top box with eye catching artwork on the top. The box top is thin cardboard and the bottom is corrugated cardboard. Inside the box is a large zip lock bag containing the most of the injection molded parts, a small zip lock bag with the clear parts, a small zip lock bag with resin parts and a small zip lock bag with some replacement parts. Also in the box is a sealed bag with some colored photo etch for the cockpit including lap belts and harness, a not colored fret with radiator grilles for the radiator and a few other parts, a very large decal sheet and a small decal sheet. Quite a haul !

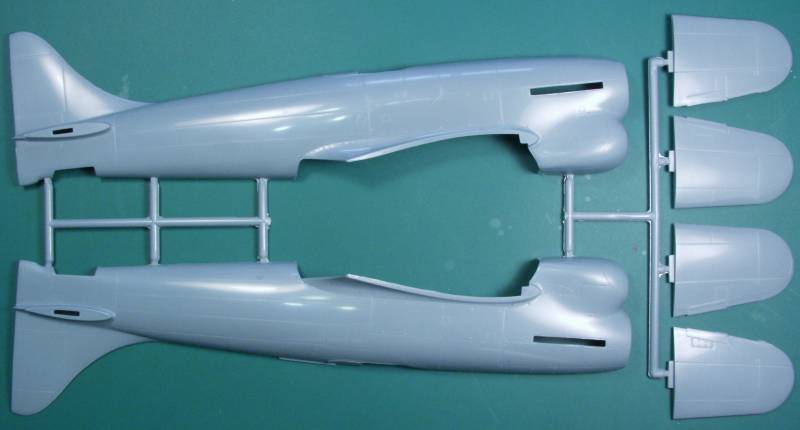

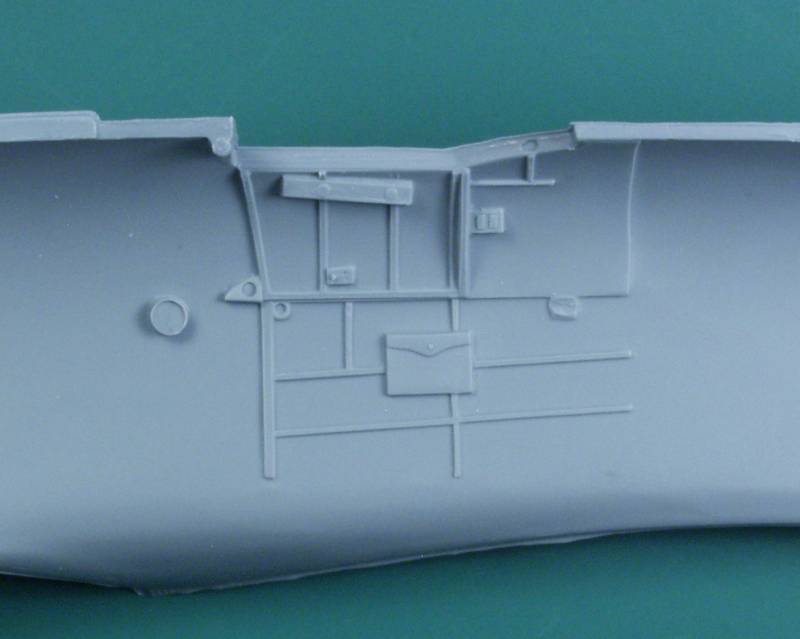

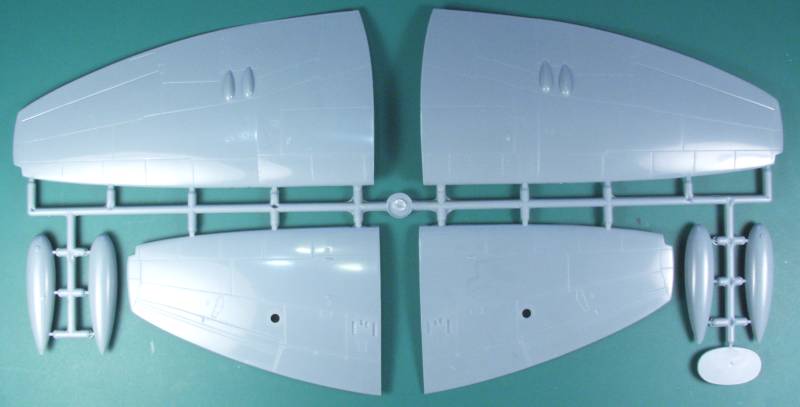

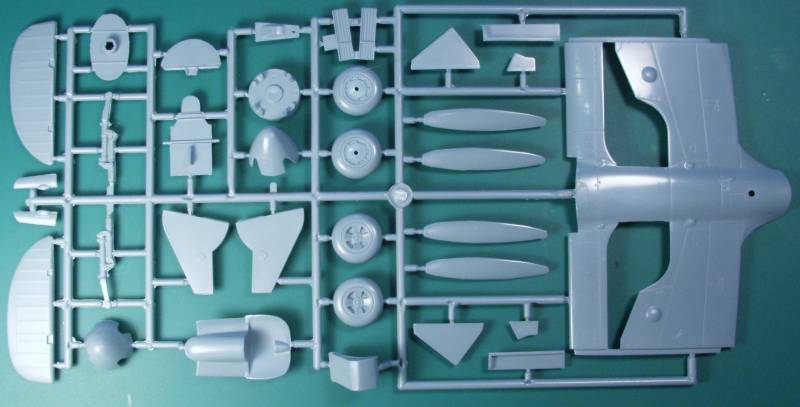

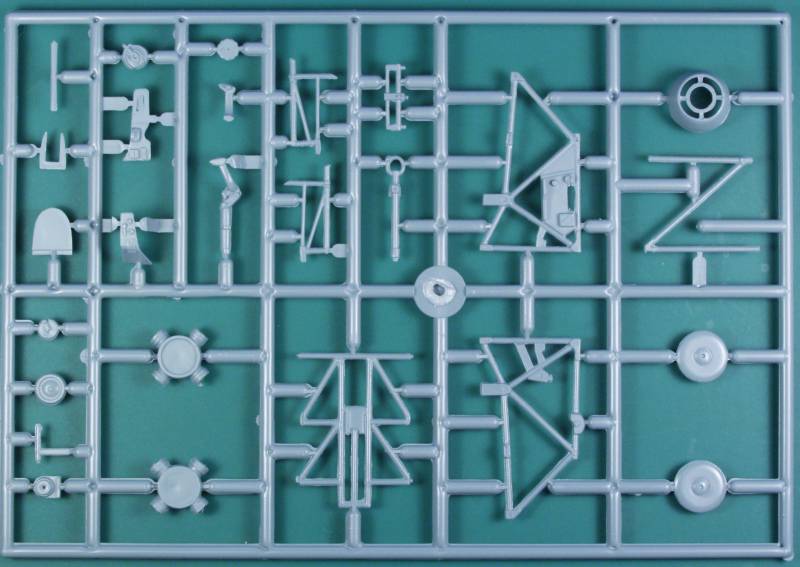

The injection molded parts are made by Sword in the Czech Republic and are typical of parts from that maker. They are molded in gray and have a glossy finish. The surface detail consists of recessed panel lines and fasteners and some raised detail where applicable. The panel lines are uniform and a nice size for the scale. As this is a limited run type kit there are no alignment pins and the sprue attachment points are fairly large. The main parts have only a trace of flash but some of the smaller parts have a good sized mold part line to clean up as well as some flash. The kit consists of three large sprues and one smaller one. Looking over the parts I found no sink marks or short shots. I did find one mark that almost looked like it could have been from a scratch in the mold dies as it was raised and one mar where parts had rubbed during transit. There are some ejector pin marks but there were only two that I could find that would show when built and they are on the inner main gear doors, which are flat and the tower should be easy to remove.

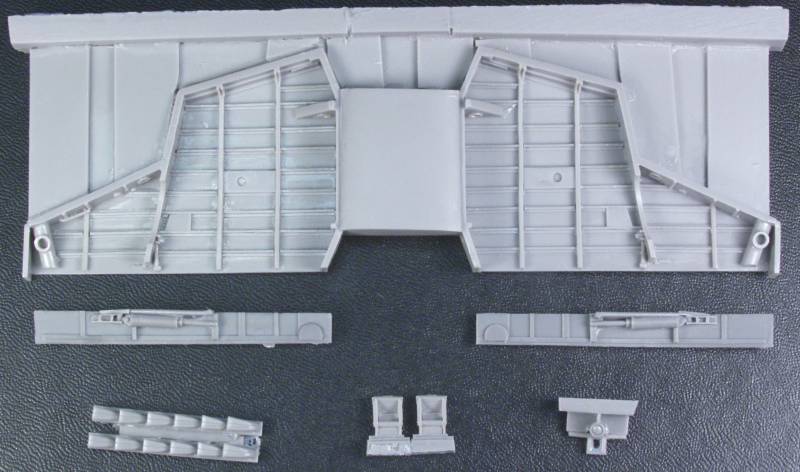

All of the control surfaces are molded in the neutral position and the hinge line looks a little shallow to me but easy to take care of with a scribe if it bothers you. The fuselage has structural detail molded inside the cockpit area and the tail wheel area as well. The shell ejector ports are not open on the bottom of the wing. The cockpit is very well appointed with both molded and PE parts. The tubular frame work combined with everything else will make for a busy and nice looking front off without buying any after market items. The wheels are molded in halves and are not weighted. The gear struts are nicely detailed but will require some amount of clean up to remove the mold parting line and flash. The main gear bays are made up of resin parts and look quite nice. The main gear doors have some nice inside detail. The propeller has separate blades and does not have alignment pins so some care required to get the pitch set. The kit includes two drop tanks. OK, lets look at the parts.

The molded on parts are nice and crisp.

Much of the work in the cockpit will center around cleaning up the mold parting lines on the tubular frame parts.

The resin parts are nicely cast and I found no pin holes or other defects. There is a lot of mold block to remove from the main casting but it does have break lines that should make cutting fairly easy. The exhaust stacks have hollowed out ends.

The parts below were supplied as replacement when early builders of the kit found that the bulkheads for the cooler were over sized, these were added to kits later along with a spinner with a more correct shape to replace on supplied with the kit. Nice service from Pacific Coat Models !

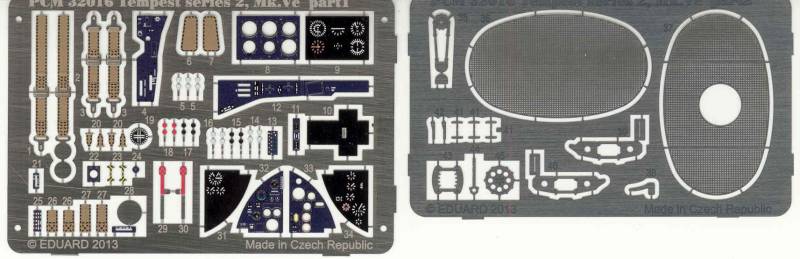

Two frets of PE supplied with the kit and made by Eduard.

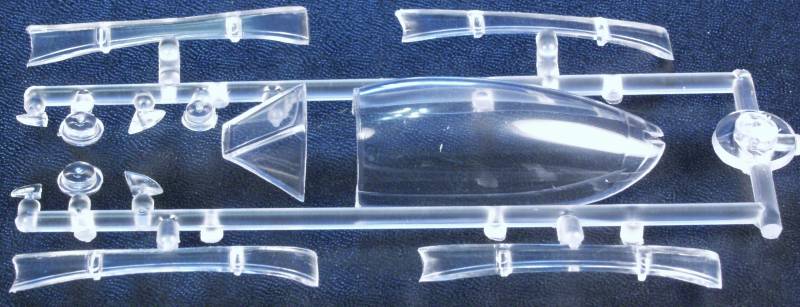

The clear parts are thin and reasonably clear, mine had a film that might have been mold release on the inside but it should clean up OK. The funny looking parts are the pylons for the drop tanks which had clear covers on them, decals are supplied for the metal frame work on these.

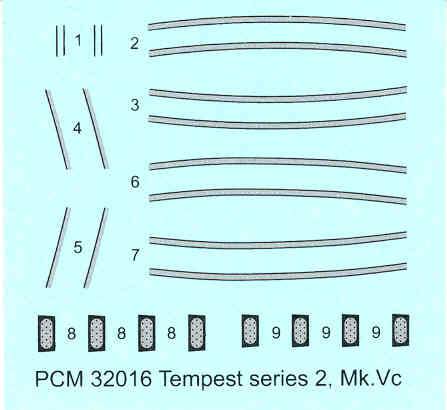

The decals, a large sheet with markings for five aircraft. They are made by Cartograf so I really don't need to say more as they make some of the best decals around. A lot of stencils are also supplied on the sheet

This small sheet is supplied for the metal frame work on the clear drop tank pylons.

The instructions are a large format booklet printed on glossy stock. The front page has some Tempest operational notes and diagrams of some of the finished assemblies, the second page features a parts map. The assembly starts on the third page following an icon chart and a paint chart that gives only numbers and generic color names. The assembly is broken into 36 steps taking up the balance of the booklet. The last page has a plan form side view and front view drawing and the back page is blank. A small folded page printed in color on glossy stock is also included showing the color schemes and decal placement for the five aircraft represented on the decal sheet.

After Market Goodies

I got these as I hate gluing wheel halves together and they are much better detailed than the kit parts. They are Barracuda Cast # BR32124.

Conclusions

While a limited run kit, this is another nice one from Pacific Coast Models. I have built their Hurricane kit and was most pleased with how it came out. The nice thing about these is that they are complete with everything you need, resin, PE, seat belts and harnesses and a great selection of decals. Like most limited run kits, expect some build challenges. Dry fit parts frequently before gluing. It is not unusual for the resin wheel bays to need thining to fit the wings properly and the wing to fuselage join on the Hurricane require different sequence for best fit than one would normally use so test, test, test ! Recommended to modelers with some limited run kit experience.

Links to kit build or reviews

A nice and informative build review can be found here.

References

Back to the 1/32 Scale British Aircraft page